The Problem

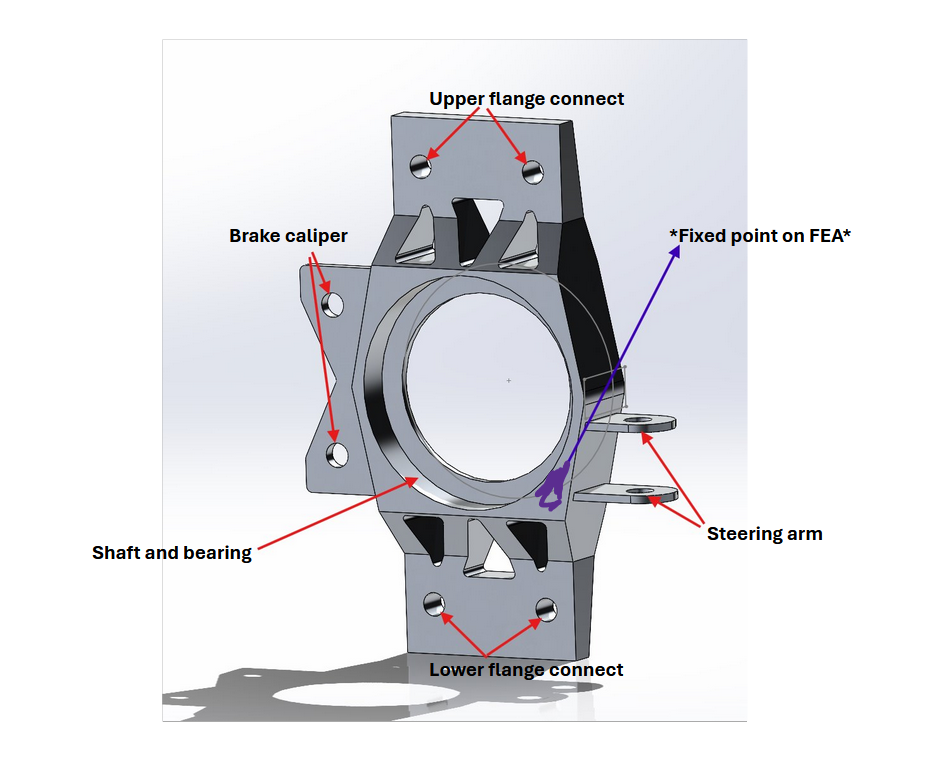

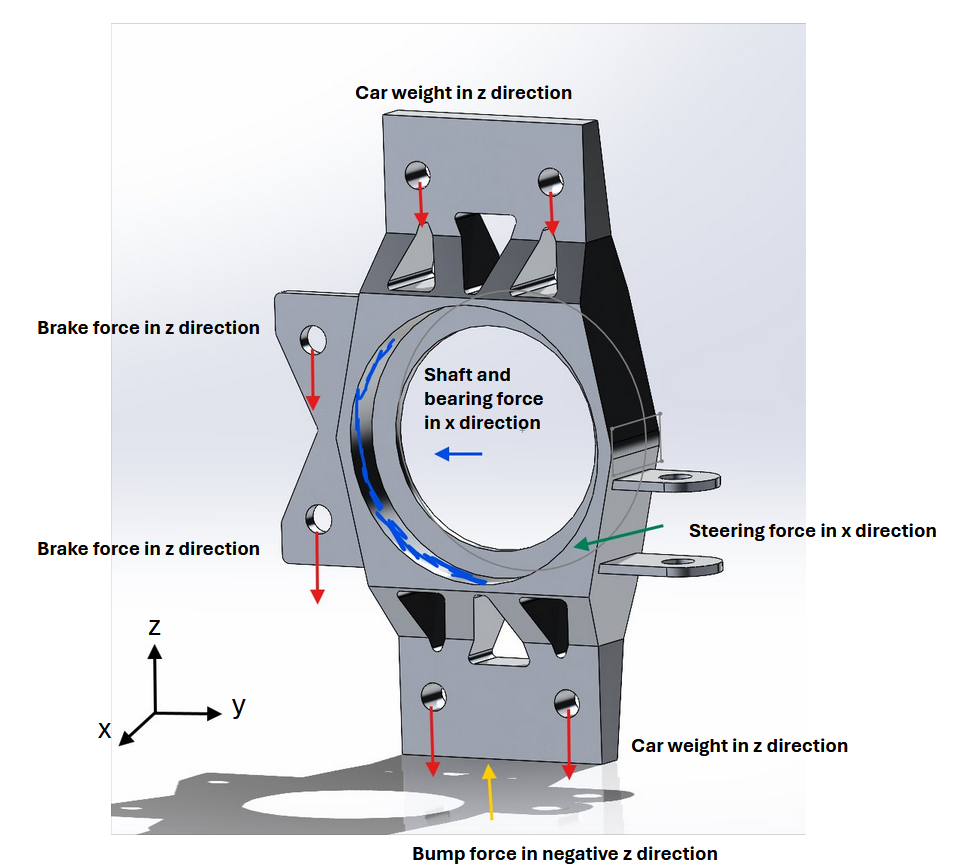

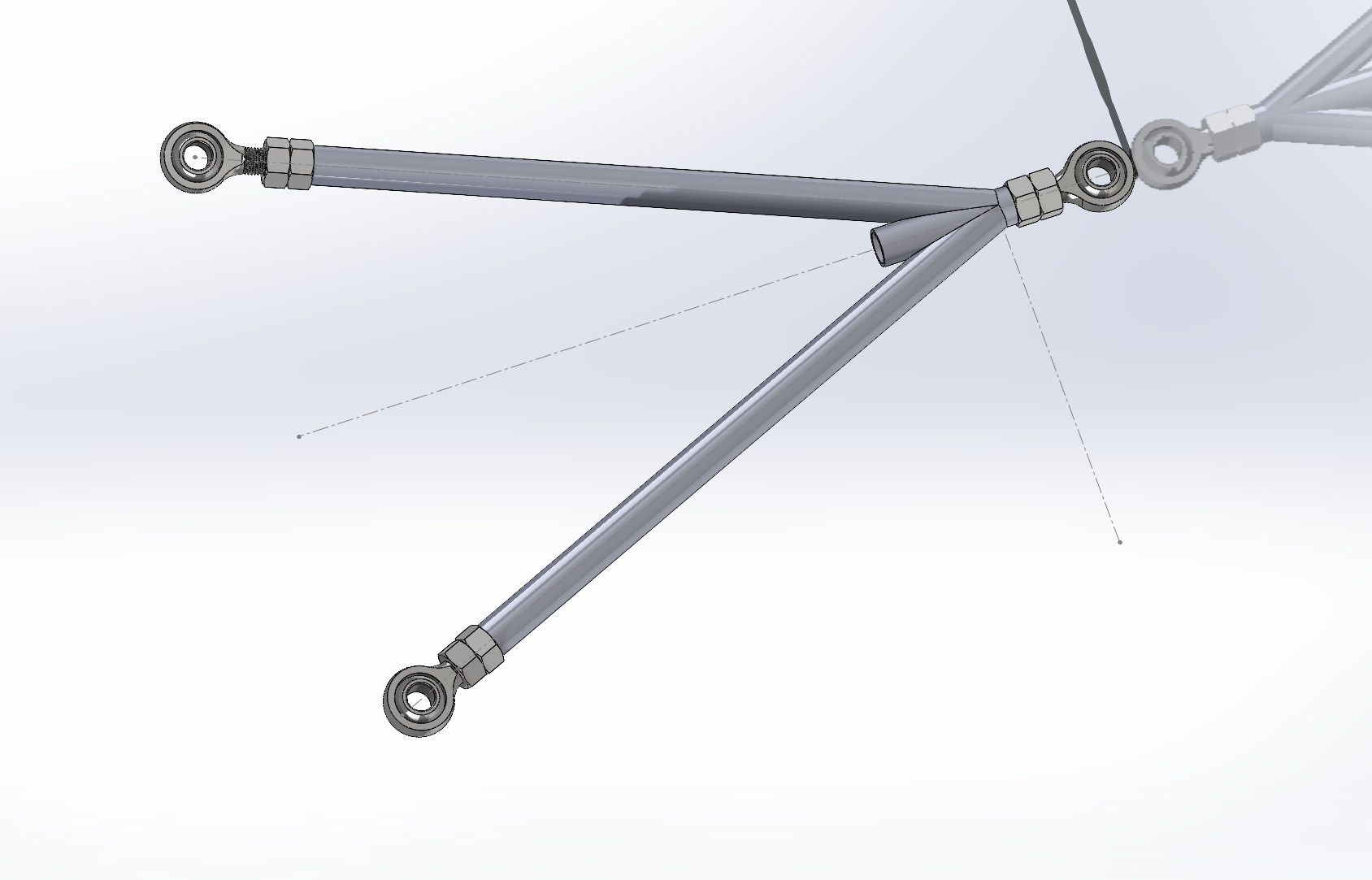

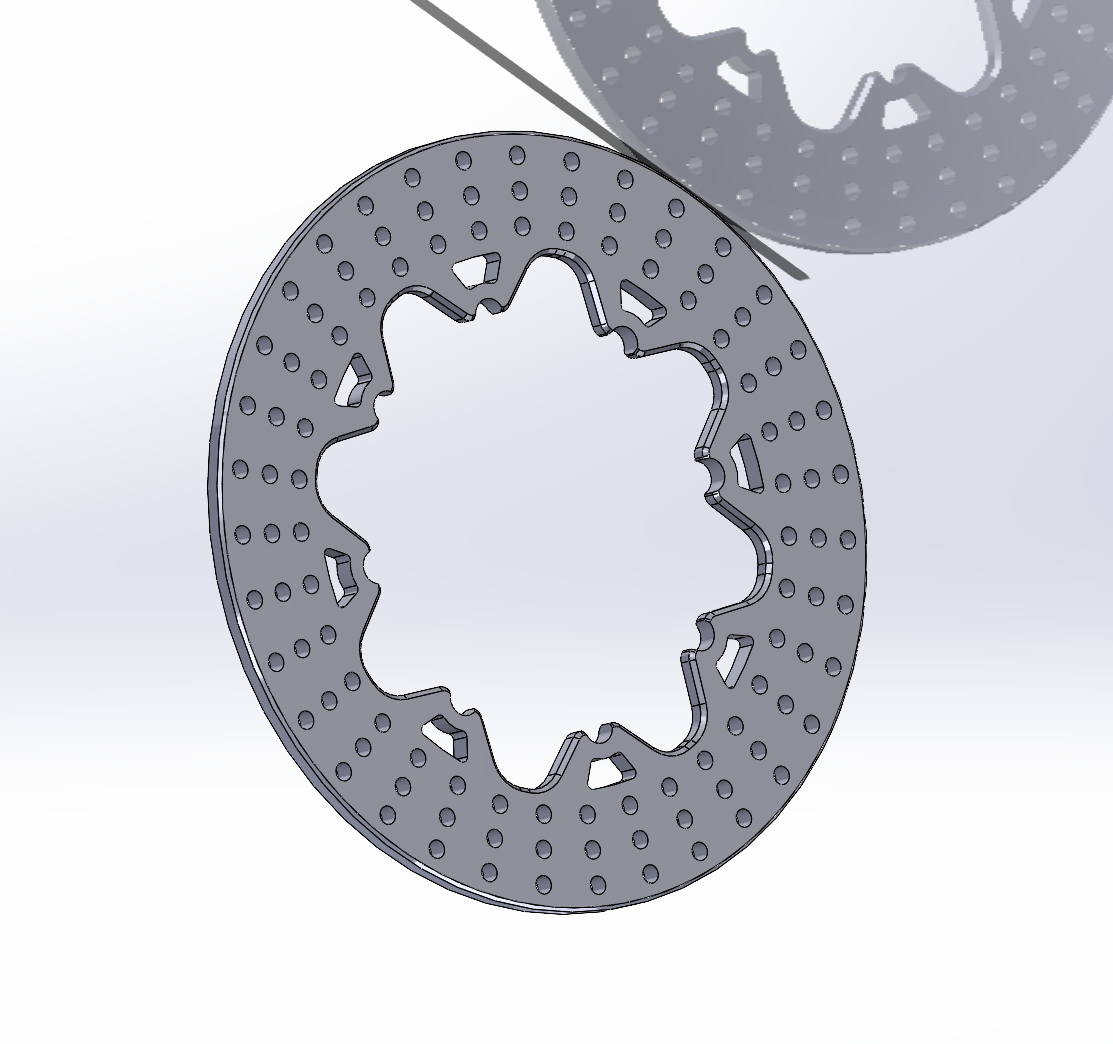

Responsible for ensuring a strong, reliable connection between the chassis and suspension system on LMU's first FSAE car. The main challenge was achieving structural integrity and precise alignment under dynamic loads while coordinating with other sub-teams to meet performance and safety standards.